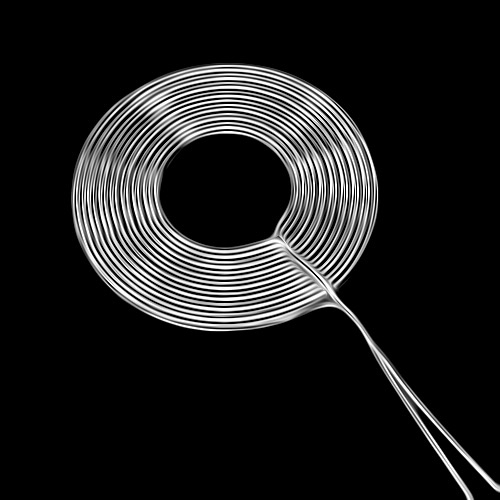

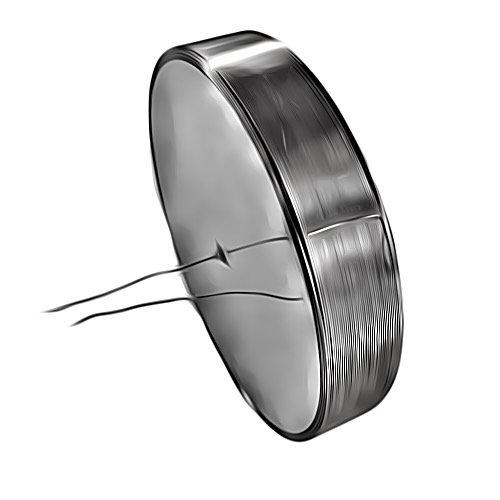

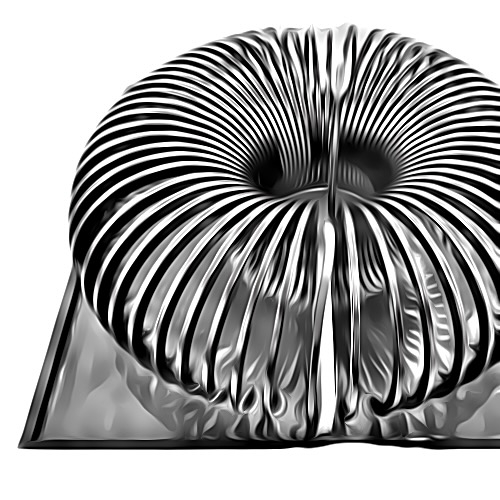

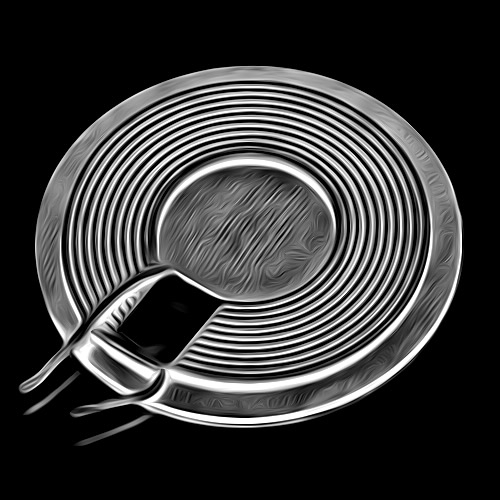

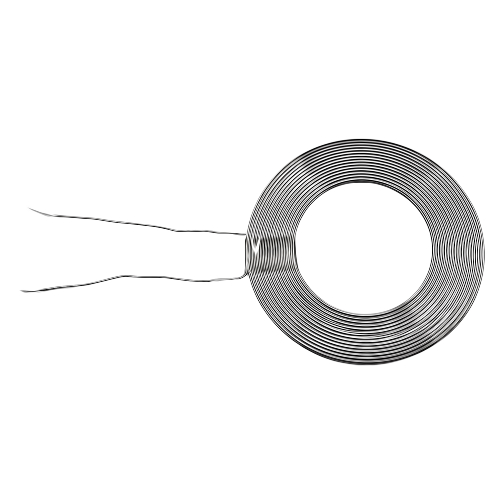

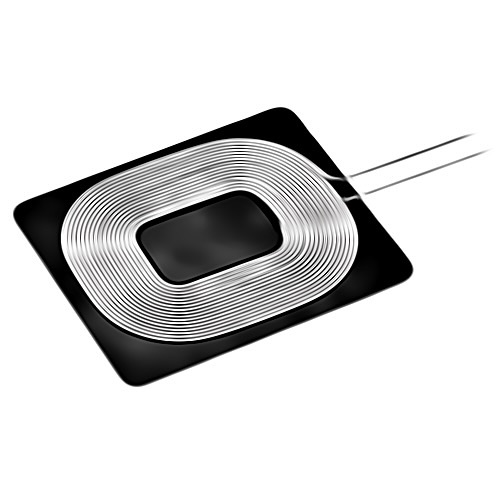

Coils belong to the passive electrical components and are often also called inductors. Coils are characterized by the fact that they are wound from several conductor loops. Applications range from chokes to antennas. The geometry of the coils does not necessarily have to be round, i.e. almost any shape - even with spatial geometry - can be realized.