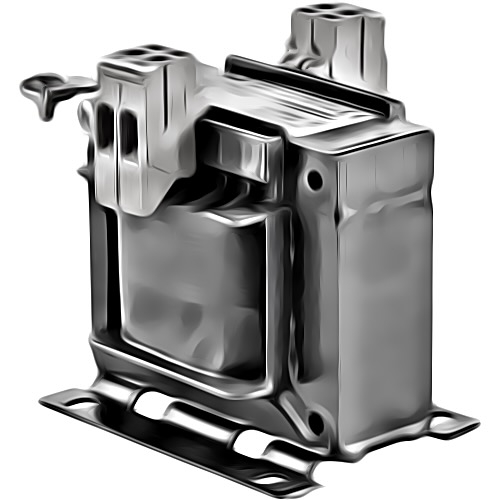

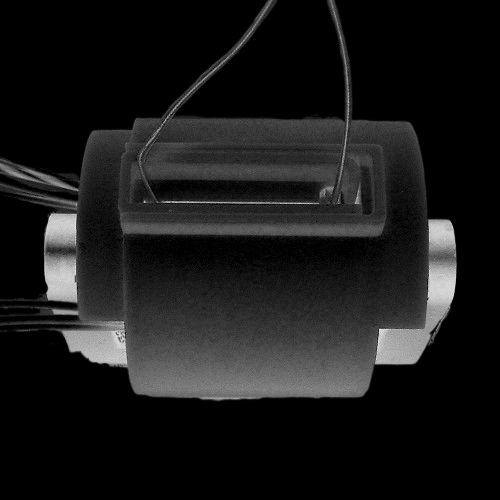

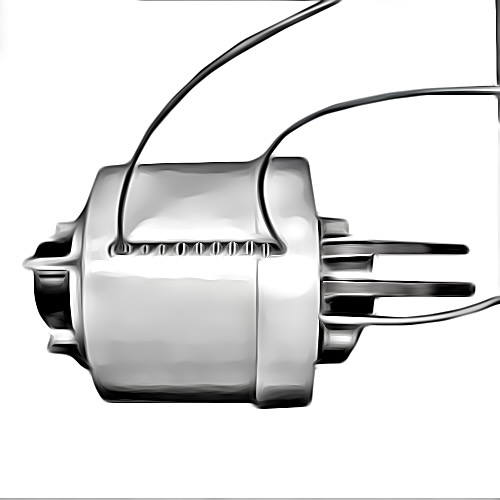

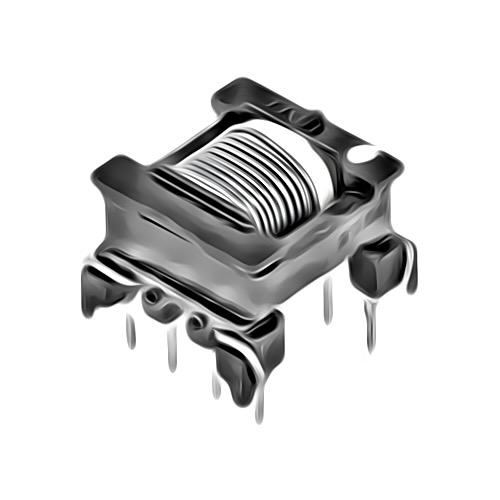

A transformer is a central component of electrical engineering and consists of at least two windings. In the simplest version, these are wound from insulated copper wire and are located on a common magnetic core. A transformer converts an input AC voltage into at least one output AC voltage, where the ratio of input and output voltage corresponds to the ratio of the number of turns of the windings.

Documents

-

Checkliste Transformatoren 353 KB

Checkliste Transformatoren 353 KB