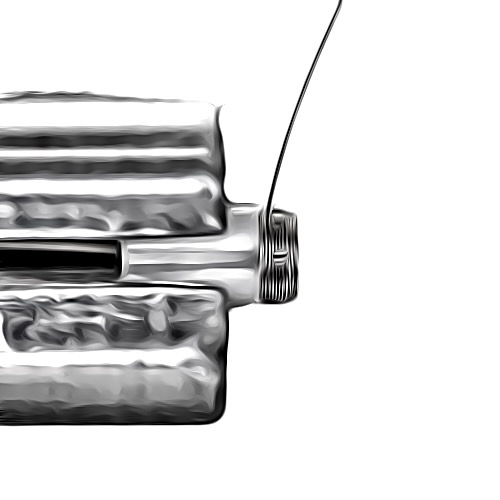

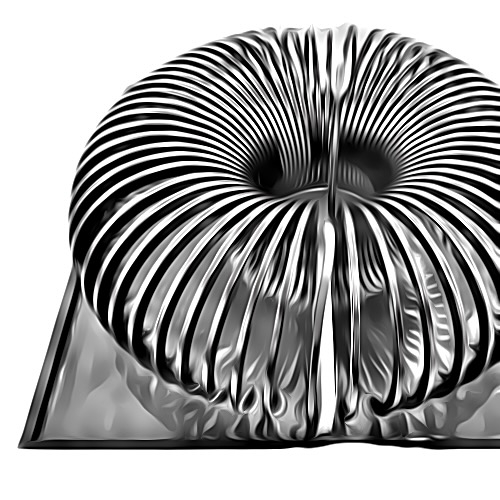

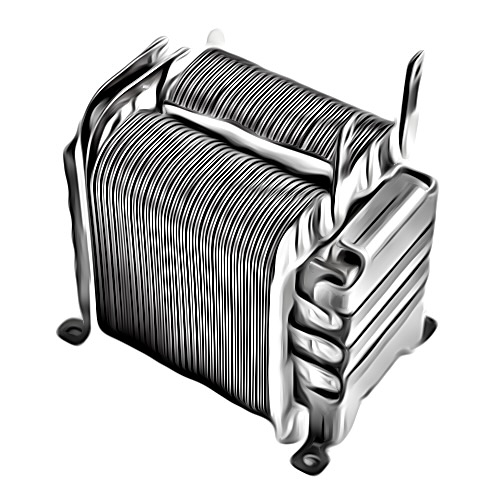

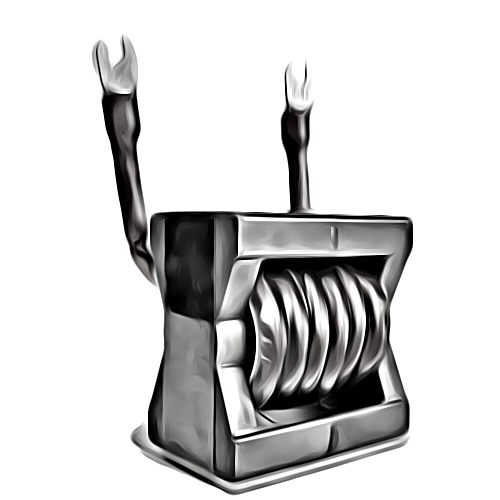

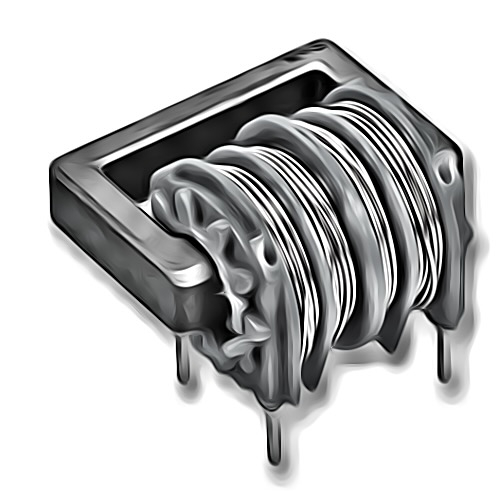

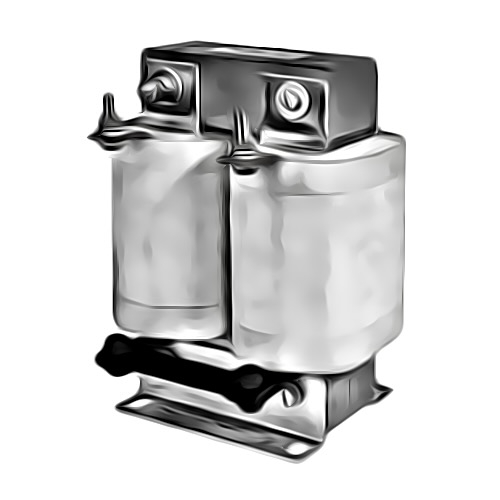

A choke is a passive component frequently used in electrical engineering and electronics which, due to its inductance, slows down the increase in current and thus has a smoothing and energy-storing effect. The term coil is also frequently used for this type of component. The physical operating principle is based on their self-induction, i.e. chokes represent an inductive resistance for alternating currents.

Documents

-

Checkliste Drosseln 211 KB

Checkliste Drosseln 211 KB