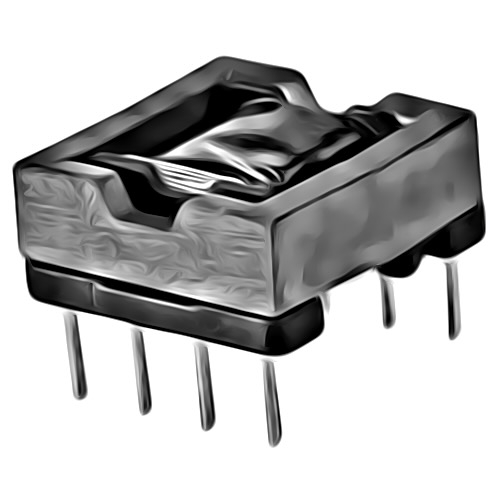

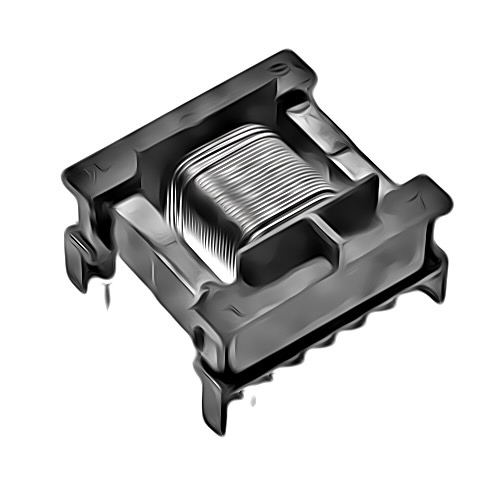

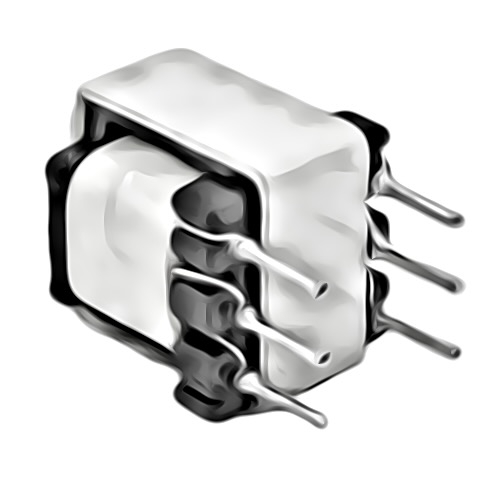

The generic term converter classically covers components that convert one physical quantity into another physical quantity. In the field of inductive components, the generic term converter is often incorrectly used primarily for components that convert one electrical quantity into another electrical quantity, e.g. voltage to voltage as in a transformer or current to voltage as in a current sensor.

Documents

-

Checkliste Wandler 223 KB

Checkliste Wandler 223 KB